QUADRATURE ENCODER

Rotary

encoder is a sensor attached to a rotating object (such as a shaft or

motor) to measure rotation. By measuring rotation your robot can do

things such as determine any displacement, velocity, acceleration, or

the angle of a rotating sensor.

1.0 Introduction

|

A

typical rotary incremental encoder consists of a light-emitting diode

(LED), a disk, and a light detector on the opposite side of the disk

(see next figure). The disk, which is mounted on the rotating shaft, has

patterns of opaque and transparent sectors coded into the disk. As the

disk rotates, the opaque segments block the light and, where the glass

is clear, light is allowed to pass. This generates square-wave pulses,

which can then be interpreted into position or motion. These pulses can

be read by microcontroller as part of a PID feedback cont System to determine translation to distance, rotational velocity, and/or angle

of a moving robot or robot part. For instance, if you have a wheel

rotating, and you want to measure the time it takes to rotate exactly 40

degrees, or if you want to know when you have traveled X distance, you

can use an rotary encoder. The encoder will be fixed on your robot, and

the mechanical part (the encoder wheel) will rotate with the wheel.

Since the output of an encoder is a square wave, you can then count the

pulses if you hook up this signal to a digital counter or

microcontroller. Knowing the distance/angle between each pulse, and the

time from start to finish, you can easily determine position or angle or

velocity or whatever. Encoders are necessary for making robot arms, and very useful for acceleration control of heavier robots. They are also commonly used in robot for maze navigation.

Rotary

Encoders usually offer 100 to 6,000 segments per revolution. This means

the encoder can provide 3.6 deg of resolution for 100 segments and 0.06

deg of resolution for 6,000 segments. Linear encoders work under the

same principle as rotary encoders except that instead of a rotating

disk, there is a stationary opaque strip with transparent slits along

its surface, and the LED-detector assembly is attached to the moving

body.

2.0 Quadrature Encoder

An

encoder with one set of pulses is sometime not sufficient because it

cannot indicate the direction of rotation. Using two code tracks with

sectors positioned 90 degree out of phase (see next figure); the two

output channels of the quadrature encoder indicate both position and

direction of rotation. For example, if A leads B, the disk is rotating

in a clockwise direction. If B leads A, the disk is rotating in a

counter-clockwise direction. Therefore, by monitoring both the number of

pulses and the relative phase of signals A and B, the microcontroller

can track both the position and direction of rotation. In addition, some

quadrature encoders include a third output channel – called a zero or

reference signal – which supplies a single pulse per revolution. This

single pulse can be used for precise determination of a reference

position. This signal is called the Z-Terminal or the index in most of

encoder. A typical, ideal quadrature signal looks like this:

With

incremental encoders, you can measure only changes in position (from

which you can determine velocity and acceleration), but it is not

possible to determine the absolute position of an object. Another type

of encoder, called an absolute encoder, is capable of determining the

absolute position of an object. Its function is similar to position

feedback using variable resistor (analog output), the only differences

are that it can be rotated in 360 degree and digital output. This type

of encoder has alternating opaque and transparent segments like the

incremental encoder, but the absolute encoder uses multiple groups of

segments that form concentric circles on the encoder wheel like a

bull’s-eye on a target or dartboard. The concentric circles start in the

middle of the encoder wheel and, as the rings go out toward the outside

of the ring, each of them has doubled the number of segments than the

previous inner ring.

To

make encoder measurements, you need a basic electronic component called

a counter. Based on its several inputs, a basic counter emits a value

that represents the number of edges (low to high or high to low

transitions in the waveform) counted. Most of the Microchip PICs have

this peripheral; normally Timer 0 or Timer 1 is used as external input

counter. External interrupt pins (INT) can also be used for counting the

pulse; the rising edge (low to high) or falling edge (high to low) is

configurable. Once the edges are counted, the next thing you need to

take care is how those values are converted to position, further to

speed and etc. The process by which edge counts are converted to

position depends on the type of encoding used. There are three basic

types of encoding, X1, X2, and X4.

2.1 1X Encoding

You

will be able to see the signals shown in the next figure if we are

scanning from left to right ; and reverse the direction or scan from

right to left on previous figure. This is a quadrature cycle and the

resulting increments and decrements for X1 encoding. When channel A

leads channel B, the increment occurs on the rising edge of channel A.

When channel B leads channel A, the decrement occurs on the falling edge

of channel A.

2.2 2X Encoding

A

shortcoming of the previous method is that the count frequency is the

same as the frequency of channel A. Thus, an encoder is said to have a

resolution of 500 pulses per revolution (ppr) does exactly that. We can

do better by using both edges of Channel A. This is not too hard to

arrange in hardware but this uses up valuable board space. The equality

test described just now works just as well if we are detecting falling

edges. Thus we can use the same routine for both rising and falling

edges and detect twice as many transitions. With 2X decoding our 500 ppr

encoder can generate 1000 pulses per revolution.

2.3 4X Encoding

It

is possible to do even better if we examine the edges of both channel A

and channel B. There are four edges for each phase of channel A and it

is possible to get 2000 pulses per revolution from our 500 ppr encoder.

When

I cut out the middle part of this signals which shown in the next

figure, we can see clearly that the two bit encoder field (A, B) is Gray Code Encoded. Only one of the two bits changes for any given state transition.

Furthermore,

we can tell whether the wheel is turning clockwise or counter-clockwise

based on the state transitions, which are mutually exclusive for the

two directions, as shown in the table below.

Most engineers will be more comfortable with the table above representing a state transition diagram, as shown in figure below.

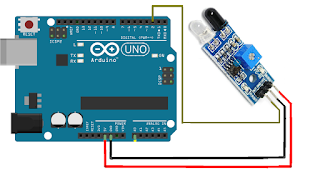

If

you have a microcontroller with the ability to generate interrupt form

external source, it is pretty simple to get the count we want. But at

least it must has two external interrupt pins for 4X encoding, let’s say

we use PIC18F4520 (3 external interrupt pins). Channel A is connected

to the INT1/RB1 pin and channel B is connected to the INT0/RB0 pin. The

sense of the interrupt is changed after each interrupt so that the

routine responds alternately to rising and falling edges. On each

interrupt, after determining the current state, we can get the direction

by checking back the previous state and Count Value will be increased

or decreased. Listing below is the example interrupt routine for

PIC18F4520 and the sequence is based on the previous state transition

diagram.

Angle

of rotation (degree) = (CountValue/XN) x 360 where N = number of pulses

generated by the encoder per shaft revolution, X is the encoding type.

Let’s say Rotary Encoder B-106-23983 (available from Cytron

Technologies) is used, N=500ppr and we use 4X encoding, so our angle of

rotation (degree) = CountValue x 0.18. This encoder outputs capable to

produce up to 100 kHz pulse, it is good enough for a normal mobile

robot. Your microcontroller speed might limit the maximum angular speed

of your encoder due to the time for serving interrupt routine. Some of

the 8-bit Microchip PIC has Quadrature Encoder Interface (QEI) feature

with noise filters like PIC18F2331, PIC18F2431, PIC18F4331 and

PIC18F4431. With this model of microcontroller, configure some of the

related registers is sufficient; position and velocity of your encoder

can be obtained directly without serving the interrupt routine

Wynn & Encore Casino: A Review of One of Las Vegas' Most

ReplyDeleteWynn and Encore 포천 출장샵 Las Vegas consist of two luxury 강원도 출장안마 hotel towers with 용인 출장안마 a total 목포 출장안마 of 4,748 spacious hotel rooms, suites 순천 출장마사지 and villas.